BMW New Patent Could Bring Worn Brake Rotors Back to Life

Forget the scrap heap — your worn brake rotors could soon be reborn.

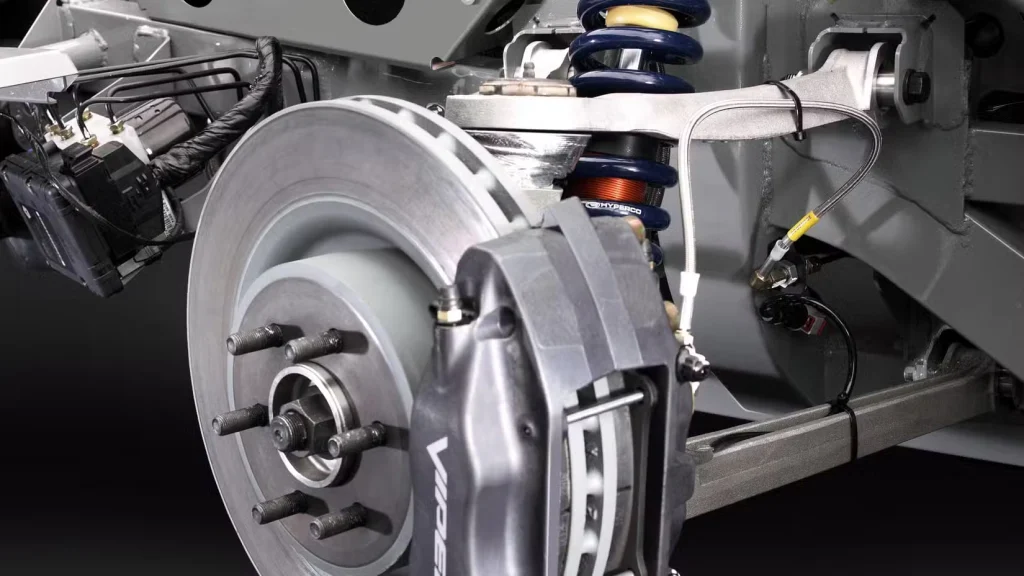

Brake rotors may be among the simplest components on a car, but manufacturing them keeps getting more expensive and resource-intensive. These hefty steel or iron discs typically serve for only a few years before ending up in the scrap stream to be melted down and cast again.

BMW, however, thinks there’s a smarter way. According to a recent patent filing with the German Patent and Trade Mark Office, the company is exploring a method that could give worn rotors—like those from a track-driven M3 Sedan—a second life.

And it’s far more advanced than a quick resurfacing job on a lathe. BMW concept involves applying a fresh layer of metal to the rotor, potentially restoring its performance and even improving it beyond the original factory specification.

Don’t Panic Over Rusty Rotors—BMW Has a Smarter Plan

The auto industry is pushing harder than ever to become more sustainable, and few sectors innovate as quickly. From recycled materials to cleaner manufacturing, automakers keep proving they can rethink even the most basic components. BMW’s latest patent might be one of the most unexpected—and intriguing—examples yet.

Normally, when iron brake rotors start to rust or wear unevenly, their fate is almost guaranteed: the trash. Some drivers still opt for resurfacing, shaving the rotor down on a lathe to make it flat again, but that practice is becoming rare. And even when it is done, the thinner rotor is more susceptible to warping during heavy braking. Recycling the metal is better than landfill waste, but melting iron down and recasting it still consumes significant energy.

BMW thinks there’s a better solution.

According to its new patent, the company wants to reprocess used rotors instead of remaking them from scratch. The process starts with sorting rotors by size or part number, followed by a detailed inspection. Anything cracked or structurally compromised gets recycled. Rotors that pass the quality check are cleaned to remove rust and surface contaminants, then sent off for the real innovation: a brand-new friction layer.

No, you can’t simply add more iron to a worn disc—but you can apply a fresh, high-performance coating that restores and potentially even enhances its braking ability. If the technology works at scale, your old rotors might not just avoid the scrapyard—they might come back better than ever.

A High-Tech Coating That’s More Than Just Paint

BMW patent outlines the use of ultra-hard materials—titanium carbide, silicon carbide, or tungsten carbide—to refurbish worn brake rotors. These compounds are commonly found in industrial cutting tools thanks to their exceptional durability and heat resistance. While they aren’t suitable for casting an entire brake disc, they’re ideal as a high-performance surface layer.

This isn’t uncharted territory, either. Porsche already uses a tungsten-carbide coating on its upgraded Surface Coated Brakes, which resist surface rust, produce less dust, last significantly longer, and offer improved fade resistance. BMW proposed reprocessing method aims to deliver similar benefits.

Applying the new friction layer works a lot like painting—if painting involved supersonic particles or industrial lasers. BMW suggests two methods: cold gas spraying or laser deposition. Cold gas spraying blasts carbide powder using nitrogen or helium at incredible speeds, causing the particles to fuse with the rotor on impact. Laser deposition, on the other hand, uses a focused beam to melt and bond the coating material directly onto the disc.

The full process includes several more technical steps. For example, the existing rotor must be measured with precision before coating to ensure the final thickness meets factory specifications.

Innovations like this could become increasingly important as Euro 7 emissions standards roll out. These regulations don’t just target tailpipes—they also govern brake-particulate emissions. A refurbished rotor with a modern, low-dust coating could help older vehicles stay compliant as they age. Even better, the approach could revive brake discs that are otherwise impossible to find. Owners of rare or aging models might end up with rotors that aren’t just restored—they’re stronger, cleaner, and more durable than the originals.